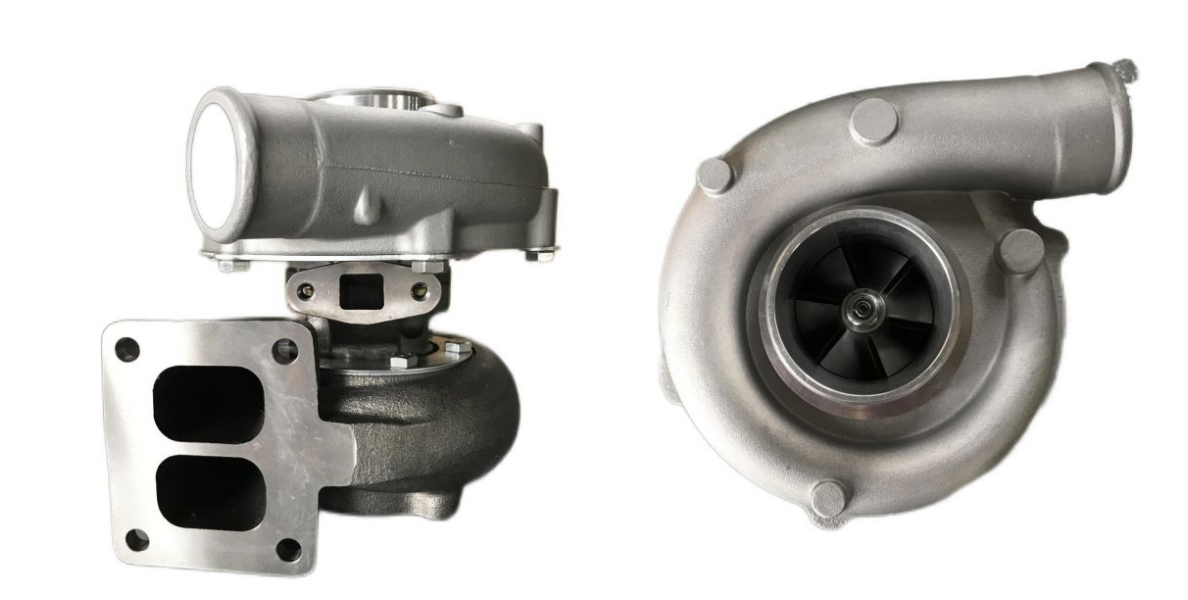

What are the reasons for the rust and oil stains on the turbocharger?

For most turbocharger and turbocharger housing manufacturers, the traditional anti-rust process will generally have the following two problems:

▲There is rust on the non-machined surface of the product, which is basically pitting in the early stage of rust.

▲There are oil spots and oil stains in the product machine and the tank, which affect the cleanliness of the product.

In fact, for machined parts like turbochargers, if there is rust or oil stains, the following 5 points can be used to analyze the reasons:

◆Cleaning: If a cleaning agent is used to clean machined parts such as turbochargers, most of them must be rinsed later, otherwise the residue of the cleaning agent may also increase the risk of rust, and will also affect the subsequent anti-rust process. Effect.

◆Anti-rust: If the anti-rust oil is used to prevent rust, the surface of the product must be clean and dry before immersing or applying the anti-rust oil, otherwise it will form a water-in-oil state with the anti-rust oil, even if it is dried later It is also impossible to exclude the contained moisture, and after a period of time, rust will appear.

◆Drying: If anti-rust oil is used for anti-rust, after drying, it is very easy to produce sludge and oil spots, which will affect the cleanliness of the product.

◆Packaging: The anti-rust bag used should be tested for anti-rust before use, and the auxiliary desiccant should be selected according to the humidity and temperature of the site, otherwise the expected effect of water absorption, dehumidification and anti-rust cannot be achieved.

◆Process control: Whether it is the machining process, rust prevention and packaging, it is necessary to control the temperature, humidity and cleanliness of the site, otherwise human sweat and environmental pollution will increase the rust probability of machined parts such as turbochargers.